Plastic Injection Molding Solutions in Malaysia | Comprehensive Manufacturing Services

At B-Pen Plastic, we specialize in plastic injection molding services in Malaysia, offering a complete range of solutions to meet diverse manufacturing needs. Backed by state-of-the-art facilities and an experienced team, we are committed to delivering high-precision, defect-free plastic components. Every stage of our manufacturing process adheres to strict quality standards, ensuring exceptional durability, reliability, and performance.

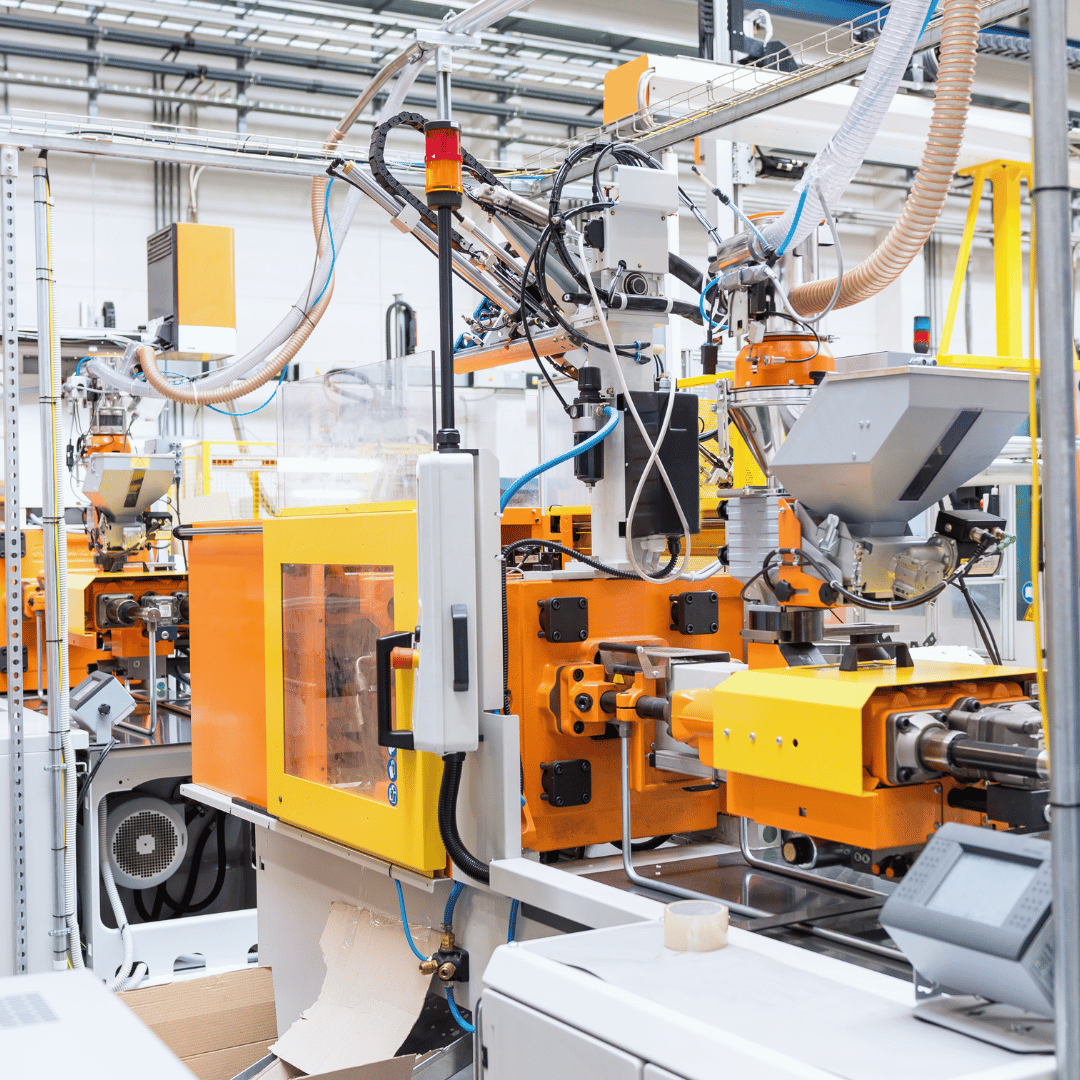

Advanced Plastic Injection Molding Equipment in Malaysia

Harnessing Cutting-Edge Technology for High-Precision Plastic Parts Manufacturing

Our Capabilities

At B-Pen Plastic, we leverage state-of-the-art plastic injection molding equipment to transform your ideas into durable, high-precision products. Our advanced machinery and industry-proven techniques enable us to manufacture a wide range of custom plastic components tailored to meet specific client needs. With a focus on superior quality, efficiency, and scalability, we support projects ranging from low-volume prototyping to full-scale mass production.

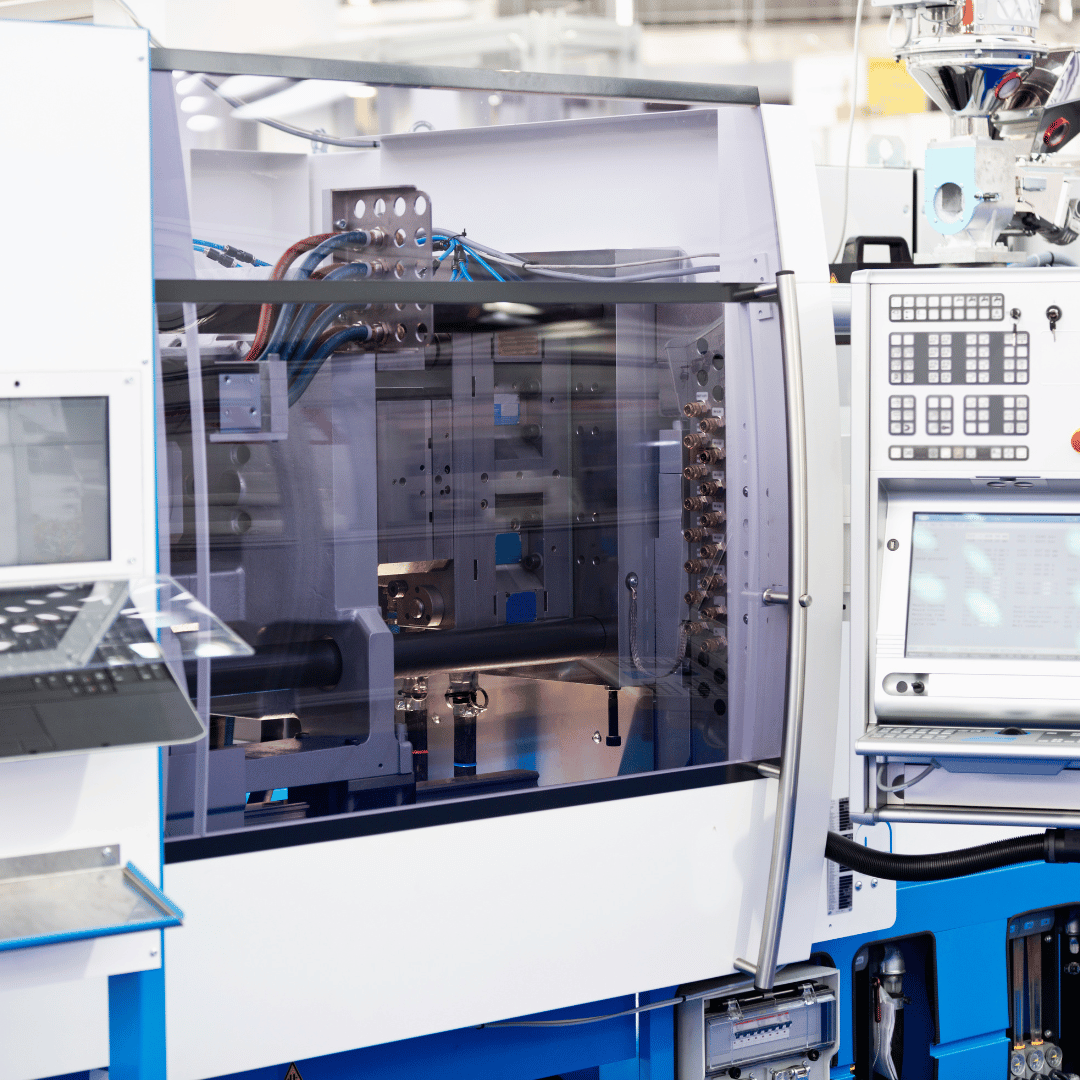

Plastic Injection Molding Quality Assurance | B-Pen Plastic Malaysia

Ensuring High-Precision Plastic Parts with Rigorous Quality Standards

At B-Pen Plastic Malaysia, quality assurance is the foundation of our plastic injection molding services. Every stage of our manufacturing process—from mold design to final production—undergoes strict quality control measures to ensure superior precision, durability, and consistency.Our comprehensive quality assurance program includes detailed inspections, functional testing, defect analysis, and continuous process improvements. By utilizing advanced technologies and skilled craftsmanship, we guarantee that every plastic component we produce meets industry standards and exceeds our clients’ expectations.

Choose B-Pen Plastic for reliable, ISO-standard plastic manufacturing solutions trusted across Malaysia.

Explore B-Pen Plastic’s Quality-Driven Plastic Injection Molding Services

Project Review & Management

Comprehensive project evaluations to ensure manufacturability, cost efficiency, and alignment with customer expectations.

Manufacturing

Precision-focused plastic injection molding process, ensuring accurate part requirements, mold integrity, and efficient mass production.

Quality Control

Rigorous quality assurance and control throughout the plastic injection molding process to deliver defect-free, high-precision parts.

Professional Support

Dedicated technical support and fast-response service to ensure smooth project progression and customer satisfaction.

Trusted by Leading Brands for Plastic Injection Molding in Malaysia

Proudly Serving Top Industries with Quality Plastic Solutions

What We Do

A Selection Of Tip Top Products

Electrical & Electronic

Plastic components for Remote Controls, Power Switches, Audio-Visual Systems, Digital Devices, Telecommunication Modules, Keypads, and Electronic Enclosures.

Automotive

Customized plastic parts for Center Console Panels, Climate Control Interfaces, Anti-Skid Snow Chain Housings, Key Buttons, and Interior Decorative Trims.

Laboratory

Specialized labware including ARACHEM Bottles, Sample Containers, Measuring Cups, Plastic Beakers, Funnels, and Secure Lid Caps — precision-molded for accuracy and durability.

Stationaries

Plastic stationery items such as Pens, Pencils, Erasers, and Desk Organizers — precision-made for daily use in offices, schools, and commercial settings.~

Household

Durable household plastic products including Buckets, Trash Bins, Plastic Containers, Laundry Baskets, and Dish Racks — designed for practicality and long-lasting use.

Others

Versatile plastic products including Washlet Toiletries, Multipurpose Buckets, and General Storage Containers — suitable for both domestic and industrial environments.~

Contact Us