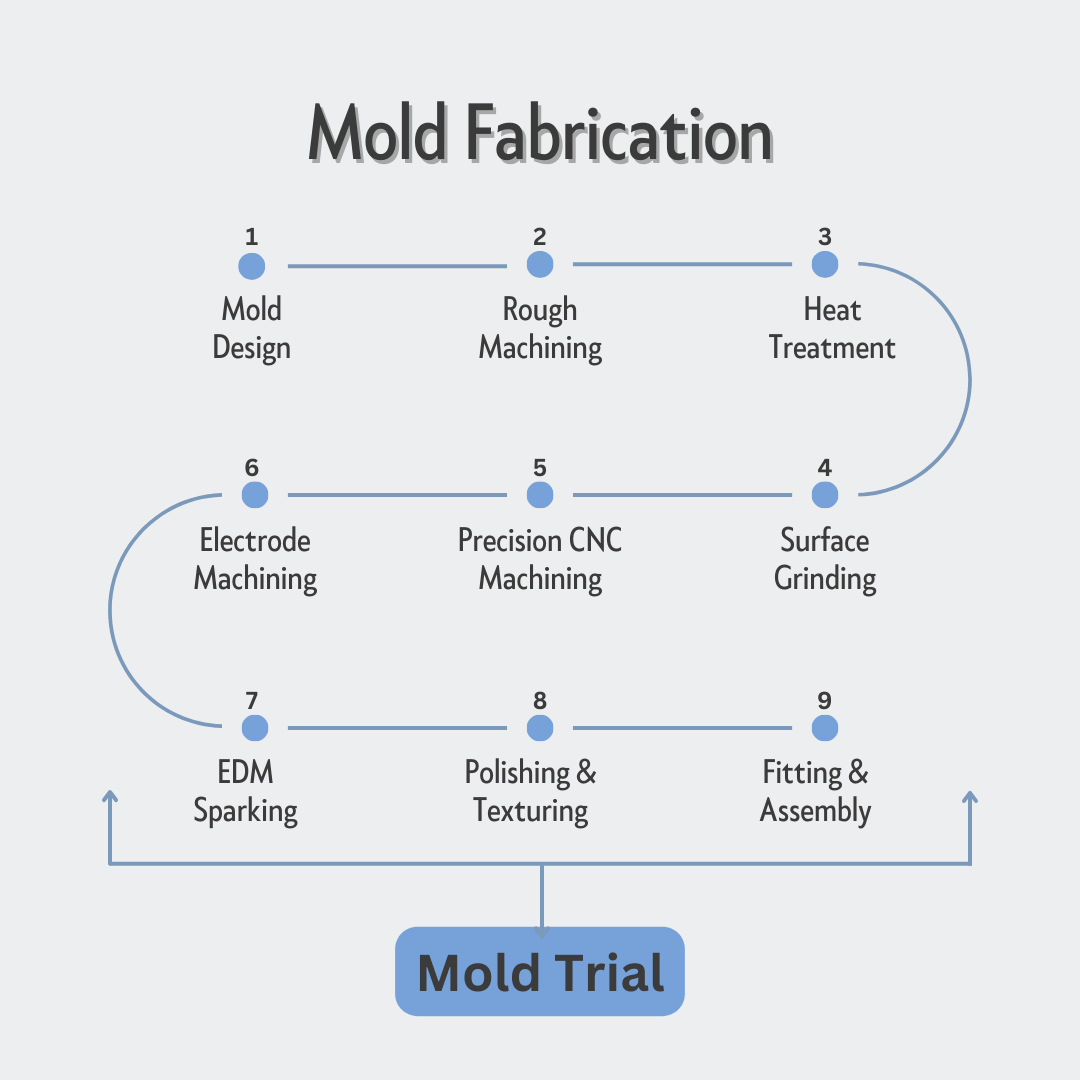

Mold Design & Fabrication

At B-Pen Plastic, we believe that precision begins with the mold. We provide end-to-end mold design and fabrication solutions that cover every phase of plastic injection manufacturing — from early concept sketches to production-ready tooling.

Leveraging decades of industry experience and advanced CAD/CAM software, our tooling development team delivers high-performance, cost-effective molds for complex and high-volume applications.

We follow the Design for Manufacturing (DFM) approach to ensure:

- Molds are optimized for material flow, part strength, and ease of ejection.

- Tools are durable enough for long production cycles.

- Each mold meets exacting tolerance, surface finish, and dimensional requirements.

Whether you need multi-cavity molds, precision core inserts, or advanced cooling channels, our mold development process guarantees maximum performance and manufacturability.

Mold Fabrication Gallery

A close-up view of CNC machining in progress at B-Pen Plastic, showcasing the fine detailing of a steel mold cavity using high-speed rotational tools. This process ensures tight tolerances and accuracy in mold fabrication for plastic injection parts.

High-precision EDM spark erosion in action, forming intricate details on a mold component at B-Pen Plastic. This advanced process allows accurate shaping of hard metal surfaces without direct contact, essential for deep cavities and tight tolerances in mold fabrication.

A close-up view of a skilled technician using a polishing tool to refine the surface of a high-cavity mold. This final finishing step ensures dimensional accuracy, smooth texture, and mold longevity—critical for producing flawless plastic parts.