Precision Plastic Parts Manufacturing in Malaysia – One-Stop Injection Molding Solutions

At B-Pen Plastic, we specialize in plastic injection molding and custom plastic parts manufacturing in Malaysia. As a trusted OEM partner, we provide a full range of services—from mold design and fabrication to prototyping, precision testing, and predictive maintenance. Our one-stop manufacturing solution helps clients achieve high-quality, durable plastic components that meet demanding industry standards.

We believe great parts start with great molds. That’s why our skilled team and advanced machinery work together to ensure each product is crafted with optimal precision, efficiency, and performance.

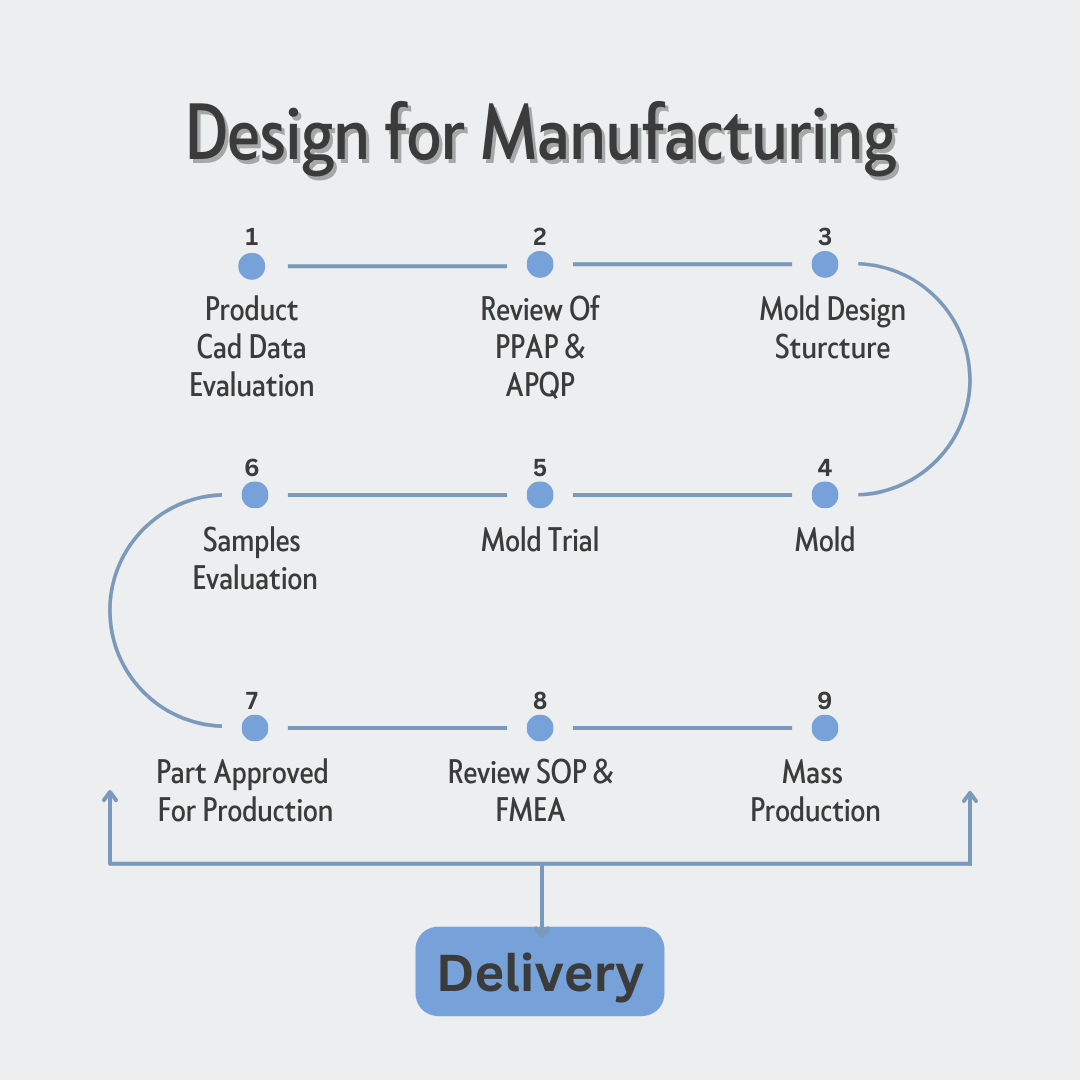

At B-Pen Plastic, our engineering and mold design team meticulously optimizes every detail—from CAD evaluation to mold structure and final part approval—ensuring seamless manufacturability. We utilize advanced CAD/CAM technologies and support industry-standard file formats like STEP, STL, IGES, DWG, and DXF for precise data interpretation.

Our “Design for Manufacturing” process accounts for key parameters such as:

- Plastic material shrinkage

- Parting lines

- Cavitation layout

- Ejector pin positioning

Each mold is crafted from durable tool steel, designed to achieve high-performance finishes and longer mold life. This process reduces production issues, enhances product reliability, and supports cost-effective mass production.

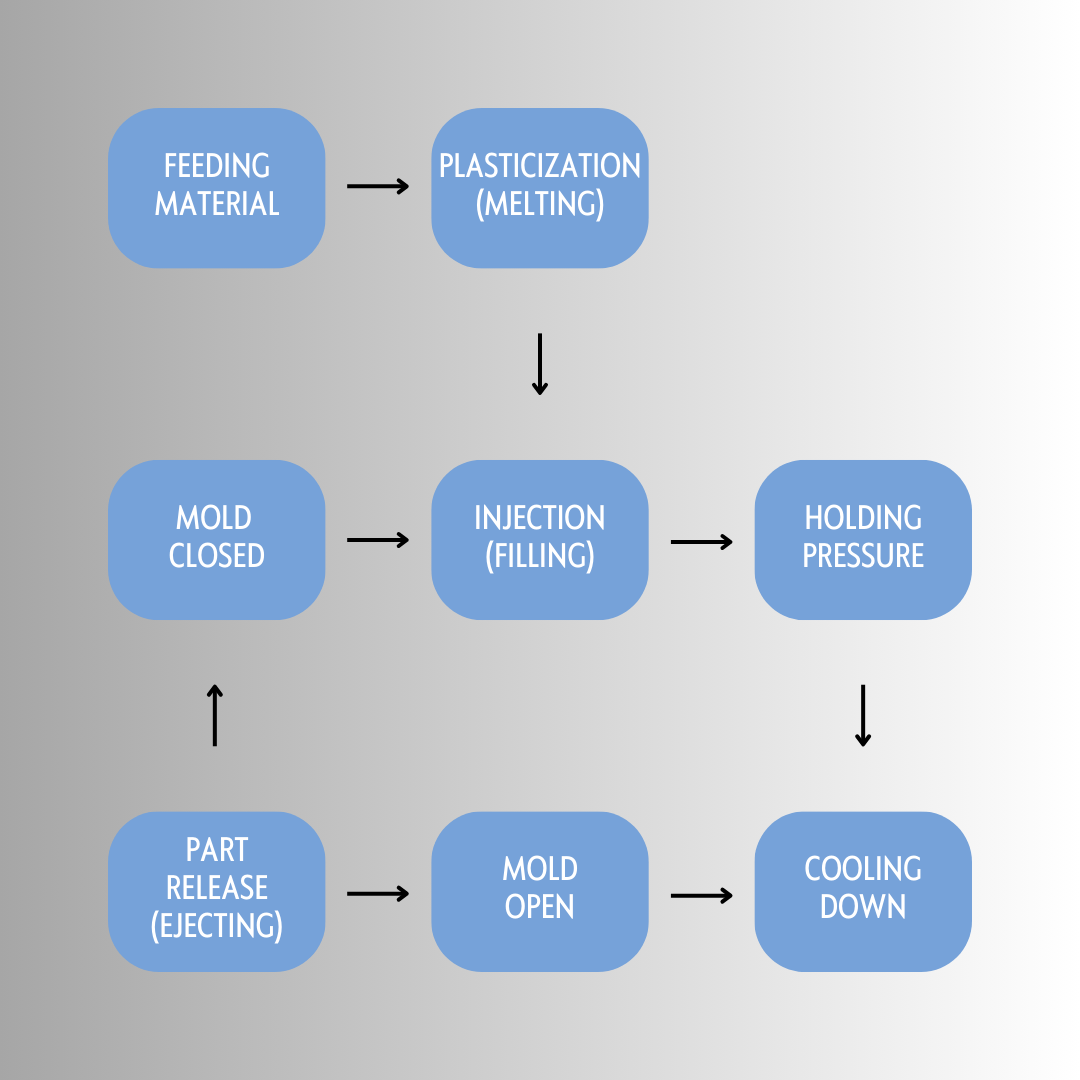

Precision Plastic Injection Molding Process

Plastic injection molding is a fast, reliable, and cost-effective manufacturing method used to produce high-precision plastic components. In this process, thermoplastic pellets are melted, injected into a mold cavity, and cooled into their final form with exceptional accuracy.

Key Parameters We Monitor:

Travel Distance for Injection, Mold-Open, and Ejection

Affects parting speed and overall process efficiency.

Temperature of Material, Mold, and Oil

Ensures uniformity and prevents product defects like warping or sink marks.

Injection, Holding, and Clamp Pressure

Maintains structural integrity and accurate cavity filling.

Injection, Cooling, and Clamp Timing

Optimizes cycle time without compromising part quality.