Ensuring Quality Beyond Expectations

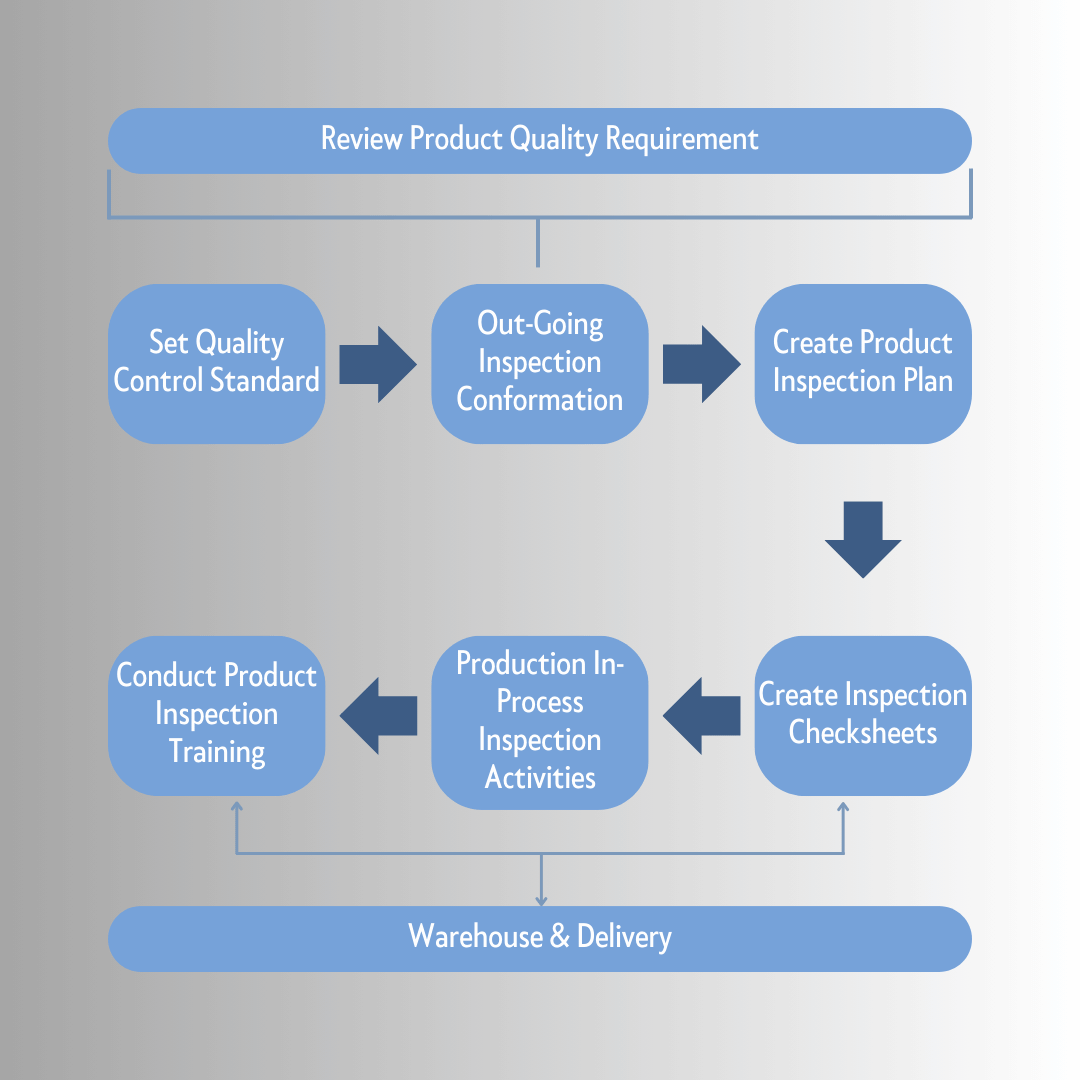

At B-Pen Plastic, quality assurance is at the heart of our manufacturing process. Our quality control begins with rigorous testing, detailed process reviews, and the creation of robust inspection plans. The goal is to identify any potential issues early, enabling corrective actions to be taken swiftly. This vigilant approach helps us consistently meet our customers’ high expectations for flawless products.

Our quality control operates on two critical levels:

- Operational Vigilance: Our operators meticulously monitor the manufacturing process, ensuring minimal variation and effective defect detection.

- Engineering Precision: Our engineers continuously assess product designs, allowing for immediate rectification of any identified issues.

The Process Control Plan at B-Pen Plastic will be meticulously crafted, addressing potential failures identified through our rigorous Process Failure Mode and Effects Analysis (PFMEA).

Our Key Quality Control Activities include:

- Supplier Capability Audit: Comprehensive validation of supplier processes.

- Raw Material Inspection: Ensuring only top-quality materials enter production.

- Pre-Production Validation: Testing and confirming parts before full-scale manufacturing.

- In-Process Monitoring: Regular inspections during production to ensure consistent quality.

- Critical Inspection: Focused checks on visual and dimensional accuracy.

- Final Quality Check: Thorough inspection of finished goods before delivery to ensure they meet customer specifications.

Understanding Plastic Injection Molding Defects: At B-Pen Plastic, we recognize that identifying and understanding common defects in plastic injection molding is crucial to improving product quality and resolving issues promptly.

Root Causes: These defects can often be traced back to issues with: